Excellent!

For their pioneering work in the standardized implementation of the digital twin, the companies WITTENSTEIN and XITASO received the Microsoft Intelligent Manufacturing Award (MIMA) in the “Scale!” category.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe challenge

In order to integrate WITTENSTEIN products and their Smart Services interoperably in to the I4.0-World, WITTENSTEIN are deploying their I4.0-Administration Shell concept. Hereby, the product data must firstly be extrapolated from existing systems like SAP and linked in a standardised format with the Administration Shell of the product entity.

Wittenstein SE

WITTENSTEIN SE develops customer-specific products, systems and solutions for highly dynamic movement, precise positioning and intelligent networking in mechatronic drive technology.

How we helped

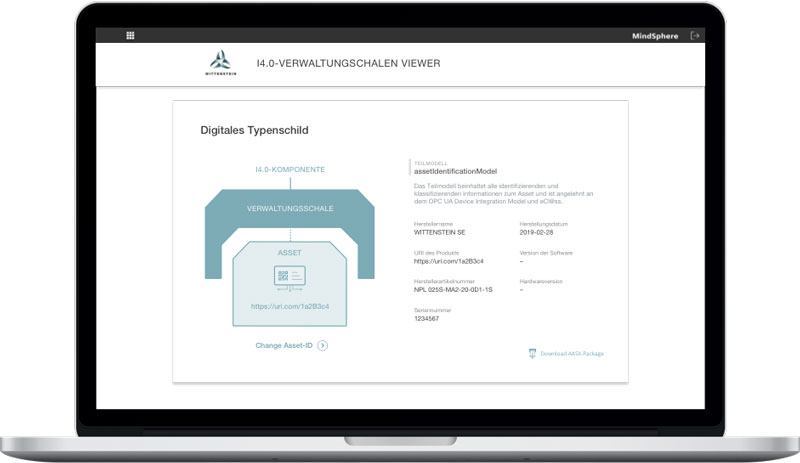

The benefits realised for WITTENSTEIN SE is a central Administration Shell Repository, which delivers product information from the Smart Services to the conventional IIoT-Platforms like MindSphere, ADAMOS or SAP AIN. Products are linked with their Administration Shell via the worldwide unique Asset-ID and described via various component models like e.g. “Identification”.

The realised MindSphere-Administration Shell-Viewer dynamically reads this component model using the Asset-ID and can be used for automatic configuration of Smart Services; the basis for further linking of components and data analysis.

Technologies

Products, which can communicate with each other

A crucial component for the successful outcome of Industry 4.0 is interoperability between components. It is the prerequisite for functioning cross-manufacturer IIoT-scenarios and the future application of Artificial Intelligence. The I4.0-Administration Shell to this end contains properties and functions of particular products and can deliver these in standardised form. Communication between and the subsequent cooperation of different products is only possible through such an Industry 4.0 compliant structure.

The ETL process

The development teams from WITTENSTEIN SE and XITASO have established and configured an ETL process (Extract, Transform, Load) to create the Administration Shell. Hereby the product data is extrapolated from the ERP-System (SAP), transformed to an I4.0-conformed data structure via Azure-Functions and delivered as a ReadDB display in Frontend. The ETL process is automated every 24 hours.

Administration Shell-Viewer

The Administration Shell-Viewer displays the component model “Identification” in V1. The Viewer-App has been integrated with MindSphere in order to demonstrate how future databases can be linked to the product with its telemetric data.

The basis for further component links and data analysis is established via the integration on the open IIoT platform. The Administration Shell is also available as an AASX-file for download and can be integrated in further services.

The administration shell as a standardized “digital twin”

The matching article in our XITASO Insights

by Christian Heinrich, IoT expert at XITASO

Other projects

Are you interested in a project, a service or do you have another question?

Dr. Michael Schackert

Phone +49 821 885882-36

michael.schackert@xitaso.com